TELESCOPIC BAND CONVEYOR SYSTEMS

Profrog Teleskopic Conveyor Systems

17 MT CASCADING TELESCOPIC BAND

--Telescopic band is a transport equipment used to carry the product to different distances. - It provides the advantage of usage to different distances by its 4 different stages connected to one main body.

-Band width: 600 mm

-Total open length: 17 mt

-Gradual telescopic band is manufactured from St 37 and St 52 sheet metal.

-It is manufactured from 6-5-4 and 3 mm metal sheets according to the design levels.

-The coating is electrostatic powder paint.

-With the main panel and front control design, it provides the operator a comfortable use.

-The speed adjustment is easily made with ABB or SIEMENS branded speed drives in the main panel.

-Telescopic band conveying capacity is 15 packs/min.

-The end-moving boom mechanism provides convenience by the height and waist alignment of the loader operator.

-The end-moving boom provides an extra 1,30 mt. to 1,50 mt extension to total band length.

-The end-moving boom movement system can be easily included to remote control panel.

-All parts are manufactured in accordance with occupational safety procedures.

-Easy use and easy assembly are advantageous.

Note : Extra band systems such as Straight, Angled and Rotation can be quoted on demand.

14 MT CASCADING TELESCOPIC BAND

--Telescopic band is a transport equipment used to carry the product to different distances. - It provides the advantage of usage to different distances by its 4 different stages connected to one main body.

-Band width: 600 mm

-Total open length: 14 mt

-Gradual telescopic band is manufactured from St 37 and St 52 sheet metal.

-It is manufactured from 5-4 and 3 mm metal sheets according to the design levels.

-The coating is electrostatic powder paint.

-With the main panel and front control design, it provides the operator a comfortable use.

-The speed adjustment is easily made with ABB or SIEMENS branded speed drives in the main panel.

-Telescopic band conveying capacity is 15 packs/min.

-The end-moving boom mechanism provides convenience by the height and waist alignment of the loader operator.

-The end-moving boom provides an extra 1,30 mt. to 1,50 mt extension to total band length.

-The end-moving boom movement system can be easily included to remote control panel.

-All parts are manufactured in accordance with occupational safety procedures.

-Easy use and easy assembly are advantageous.

Note : Extra band systems such as Straight, Angled and Rotation can be quoted on demand.

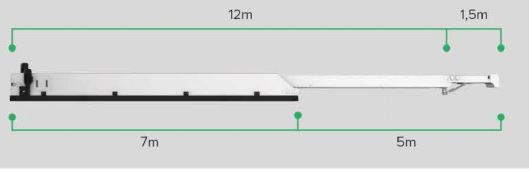

12 MT CASCADING TELESCOPIC BAND

-Telescopic band is a transport equipment used to carry the product to different distances. - It provides the advantage of usage to different distances by its 2 different stages connected to one main body.

-Band width: 600 mm

-Total open length: 12 mt

-Gradual telescopic band is manufactured from St 37 and St 52 sheet metal.

-It is manufactured from 5-4 and 3 mm metal sheets according to the design levels.

-The coating is electrostatic powder paint.

-With the main panel and front control design, it provides the operator a comfortable use.

-The speed adjustment is easily made with ABB or SIEMENS branded speed drives in the main panel.

-Telescopic band conveying capacity is 15 packs/min.

-The end-moving boom mechanism provides convenience by the height and waist alignment of the loader operator.

-The end-moving boom provides an extra 1,30 mt. to 1,50 mt extension to total band length.

-The end-moving boom movement system can be easily included to remote control panel.

-All parts are manufactured in accordance with occupational safety procedures.

-Easy use and easy assembly are advantageous.

Note : Extra band systems such as Straight, Angled and Rotation can be quoted on demand.

SACK PRESSING SYSTEM

-The mechanism ensures the maximum use of the stock and shipping area of the products packed in sacks.

-Produced accordance with 25-50 kg sacks.

-With its modular structure and ergonomic design, it can be integrated to all needed mechanisms

-A gradual change in volume can be provided by 3 rolls

-2 different motors are used. 1 is 2,2 kw 47 Rpm drive and 1 is 0,75 kw 23 Rpm volume adjustment motor.

-Provides easy maintenance performing on the machine without disassembling it during maintenance thanks to its maintenance covers.

-Works synchronously with the telescopic band by mounting on the main body.

-Suitable with all cascading bands.

Note : Extra band systems such as Straight, Angled and Rotation can be quoted on demand.

HYDRAULIC UNIT SYSTEM

-The vertical position is done controlled with the piston suitable with the band weight and hydraulic system.

-Provides advantage of reaching heights with the hydraulic body system.

-Hydraulic unit is included in the band control system.

-There are two hydraulic pistons in the main chassis.

-With the hydraulic pistons, the telescopic band can heighten rigidly from the ground to the determined heights.

-2 hydraulic pistons are used in the band chassis.

-All parts are included like piston, hose etc.

Note : Extra band systems such as Straight, Angled and Rotation can be quoted on demand.

CHASSIS BAND SYSTEM

-It is the chassis production required for the height determined from the ground and ceiling of the telescopic band.

-Chassis dimensions are produced according to the dimensions specified in the project study.

-It is shipped in disassembled condition and is easy to assemble.

-It is produced with NPU and angle irons suitable for the band weight.

Note : Extra band systems such as Straight, Angled and Rotation can be quoted on demand.