Flour Improvers

Why Flour Improvers?

The importance of flour improvers in the sector is quite great, especially in terms of bakery products, bread, pastry and general food industry.

Here are the main reasons:

1.Standardizing Flour Quality

Flours obtained from wheat harvests can vary depending on the region, climate and harvest season. Flour improvers balance these differences by:

Improving the workability of the dough,

Making the end product quality consistent.

2.Improving Dough Properties

Thanks to flour improvers:

The water-holding capacity of the dough is increased,

Elasticity and gas retention are improved,

The fermentation process is controlled.

In this way, the product rises better and the texture is softer.

3.Enhancing Final Product Quality

Flour improvers improve the product’s:

Pore structure,

Color,

Taste and aroma,

Shelf life.

This consistency is critical, especially for large bakery chains.

4.Cost and Efficiency Benefits

Good improvers can provide the desired quality even with low-quality flour. This means:

Savings in raw materials,

Less waste in production,

Lower costs.

5. Regulatory and Functional Requirements

In some countries, it is mandatory to add vitamins/minerals (e.g. iron, folic acid) to flour. Such enrichment processes are also done with flour improvers.

In short, flour improvers are strategic components that directly affect the quality, sustainability and economic value of not only the flour but also the final product. Especially in industrial production, using flour without improvers is commercially risky.

World Breads

Turkish Bread

Usage Area

In Traditional Turkish Bread Flour Production Processes, 10-30 gr/ 100kg

Benefits

In the production process of traditional Turkish breads from flours with different quality values;

- It ensures controlled formation of the dough during the kneading phase.

- It ensures dough strength during the fermentation process;

- It supports dough stability during fermentation development.

- It improves volume, color, blade and freshness properties in final products.

ADKMATE600

ADKMATE605

ADKMATE610

ADKMATES00

ADKMATE805

ADKMATE810

ADKMATE615

ADK MATE 615 EGE

ADK MATE 615 KARADENİZ

ADK MATE 615 İÇ AND

ADK MATE 615 MARMARA

ADK MATE 615 GDOĞU

ADK MATE 615 AKDENİZ

French Baguette

Usage Area

It is used to ensure product standards in flour exports and to increase the tolerance of products in adverse weather conditions that may occur during the operation period. 10-30 gr / 100 kg

Benefits

- It provides controlled formation of the dough during the kneading phase.

- It provides dough strength during the period until fermentation.

- Easy to process dough provides homogeneous and fine porous structure in bread.

- It provides crispy crust, late staling and good volume.

ADKMATE100

ADK MAYE 100 BGT

English Toast Bread

Usage Area

It is used to ensure product standards in flour exports and to increase the tolerance of products in adverse weather conditions that may occur during the operation period. 10-30 gr / 100 kg

Benefits

- It provides a highly elastic dough structure.

- It provides regular pore distribution in the dough’s internal structure.

- It provides standard color distribution during the cooking phase.

- It prevents shrinkage from the sides of the mold.

- It preserves its freshness and softness for a long time.

ADKMATE120

Lepyoshka Bread

Usage Area

In Tandoori Bread and Uzbekistan Leposhka Bread Flour Production Processes

10-30 gr / 100 kg

Benefits

In the Tandoori Bread Production Process,

- Provides dough strength.

- Prevents dough from falling out of the tandoori by preventing it from flowing.

Prevents deformation in the final product.

Preserves its unique taste and smell in tandoori bread.

ADKMATE625

Openable Pruducts

Traditional Solutions

Pita & Lavash

Usage Area

In the production processes of Pide and Lavash;

10.0-15.0 gr / 100 kg

Benefits

The most developed bread type is the spreadable bread. There is a lot of cultural diversity in this bread group and the desired quality criteria for each product type differ.

ADK MATE 905 and ADK MATE 910 product series, which provide features such as dough elasticity, crust color, inner softness, crispy structure, and preservation of freshness for 2-3 days, offer excellent results to our business partners.

ADKMATE905

ADKMATE910

ADK MATE 910 P

ADK MATE 910 L

ADK MATE 910 PL

Openable Dough

Usage Area

In the production processes of yufka flour;

5.0-10.0 gr / 100 kg

In Traditional Turkish Bread Flour Production Processes,

10-30 gr / 100kg

Benefits

- It gives high elasticity to the dough.

- It does not tear when opened by hand.

- It is suitable for use in all industrial phyllo machines.

- It does not tear or break along the production line.

- It is easy to process, it can be opened to the desired thickness.

- It does not make edges and provides homogeneous opening and does not stick.

- It has a high water retention capacity in the dough irrigation process.

- There is no decay in the recycled dough.

ADK MATE 915 (BAKLAVALIK)

ADK MATE 915 YFK

ADK MATE 915 M-YFK (MAKİNE)

ADK MATE 920 YFK

ADK MATE 920 BKV

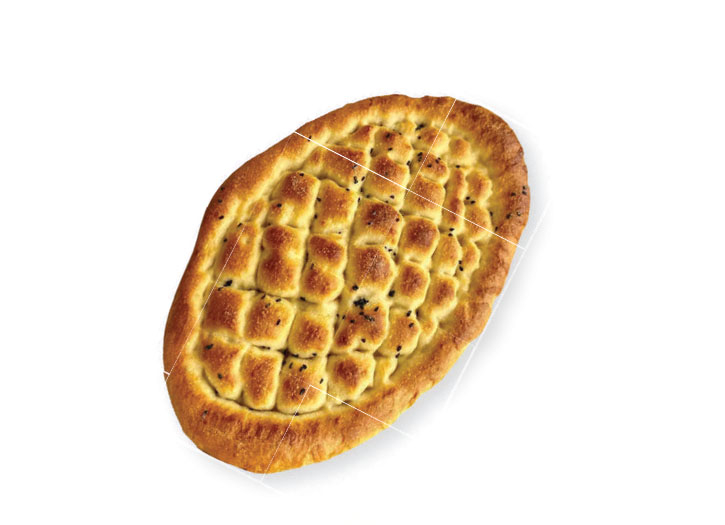

Ramadan Pita

Usage Area

In Ramadan Pide Flour Production Processes;

10-30 gr / 100 kg

Benefits

- In the Ramadan Pide Production Process,

- It improves the water retention capacity of the dough.

- It ensures easy processing and opening of the dough.

- It preserves the shape given to the dough (nail retention).

- It improves the volume, color and freshness properties in the final products.

ADK MAYE 830 RP

Trabzon Bread

Usage Area

In Trabzon Vakfıkebir Bread Bread Flour Production Processes;

10-30 gr / 100 kg

Benefits

- Trabzon Taş Fırın Bread is the only bread that is unique not only in Turkey but also in the world with its history, oven, cooking, shape, taste and non-stale feature.

- In the Trabzon Vakfıkebir Bread Production Process,

- It provides controlled formation of the dough during the kneading phase.

- It provides dough strength and stability during the long fermentation period.

- It provides easy workability in the dough.

- It provides volume, bright color and the desired crust structure in the final product.

ADK MAYE 815 TRBZ

Traditional Solutions

Variety

Pasta & Noodle Improver

Industrial Solutions

Kayseri Pita

Usage Area

In Kayseri Pide Flour Production Processes;

10-30 gr / 100 kg

Benefits

- In Kayseri Pide Production Process, it improves the water retention capacity of the dough.

- It optimizes fermentation development, supports fermentation stability and strength.

- It provides easy opening and workability in the dough.

- It improves the volume, color and freshness properties in the final products.

ADK MATE 620

Pastry Flour

Usage Area

In Variety and Pastry Flour Production Processes;

10-30 gr / 100 kg

Benefits

- In the production process of various and pastry products,

Increases the kneading and processing tolerance of the dough. - Provides the fermentation resistance of the dough, supports the dough stability.

- Provides the dough with a structure that will carry the fat content.

- Tolerates the margin of error in the final products.

- Improves the volume, brightness and freshness properties.

ADK MATE 820

Pasta Noddle

Usage Area

In Pasta and Noodle Production Facilities, ADK MATE 130 Pasta and Noodle Improver;

10-15 gr /100 kg flour

Benefits

- By optimizing the dough rheology during the process, it prevents breakage and cracking during the drying phase.

- Reduces the appearance of stains.

Increases the surface hardness of the pasta. - Provides the desired final product color and brightness.

- Provides improvement in the product chewiness after cooking and prevents sticking.

ADK MATE 130 PASTA NOODLE

Tortilla Improver

Usage Area

Tortilla – Chapati and Pita Bread ADK MATE 400 TRTL-CHAPATI-PITA

100-200 gr/100 kg flour

Benefits

In types of flatbreads with high water and fat content that can be opened by kneading, where the dough development period is provided;

- Preservation of shape (diameter does not shrink),

- Prevention of edge breakage,

- Gaining dough and process stability,

- Prevention of mold throughout shelf life (6-9-12 months).

ADK MATE 400 TRTL-CHAPATI-PITA

ADK MATE FLEX

Industrial Solutions

Toast, Hamburger & Sandvich Bread Improver

Usage Area

In Toast – Sandwich and Hamburger Bread Production Facilities;

100-200 gr/100 kg flour

Benefits

- A dough structure with high elasticity,

- Regular pore distribution in the dough’s internal structure,

- Standard color distribution during the cooking phase,

- Prevents collapse from the sides of the mold, Provides long-term freshness and softness.

ADK MAYE 400 YOSY-SNDWCH

ADK MAYE 400 HBURGER

Biscuit, Wafer & Cracker Improver

Usage Area

Protease enzymes are used in fluid dough processes such as biscuits, wafers, shredded wheat, etc.

10 – 20 gr / 100 kg flour

Benefits

- Proteases,

- Provide hydrolysis of gluten protein bonds.

- Decreases the index value of flour.

- Reduces dough resistance.

- Provides elastic and easily shaped dough.

- Decreases the softening and stability values of dough.

- Decreases water absorption capacity.

- Improves flavor and browning.

- Provides energy and time savings in businesses.

ADK MATE F-PRO

ADK MATE B-PRO

ADK MATE FB-PRO

Croissant, Pufy Pastry & Frozen Dough Product Improvers

Usage Area

In production facilities that use frozen dough (croissant, puff pastry and all frozen dough);

100-200 gr/100 kg flour

Benefits

Frozen dough, which is a successful method developed in line with technological advances in the bakery sector, allows businesses and consumers to offer easy-to-prepare and delicious products. ADK MATE 400 SOFT and ADK MATE 400 SOFT D frozen dough improvers, which reduce transfer costs and provide storage and labor savings, prevent deformations that may occur in the dough during thawing and offer standard products with short thawing and baking times.

ADK MATE 400 SOFT

ADK MATE 400 SOFT D

Pastry & Variety Product Improver

Usage Area

In various bakery products production facilities such as pastry, buns;

100-200 gr/100 kg flour

Benefits

- Increases dough tolerance to kneading and processing

- Provides dough with structure to carry fat content.

- Supports dough’s fermentation resistance and stability.

- Tolerates margin of error in final products.

Improves volume, shine and freshness properties.

ADK MAYE 400 ÇEŞİT

Industrial Solutions

Bagel

Vitamin & Mineral Solutions

Pizza Improver

Usage Area

In Pizza Production Facilities; 100-200 gr/100 kg flour

Benefits

- It provides more product due to its high water absorption,

- Easy processing during production,

- Easy opening and tearing during dough rolling,

- Providing the desired homogeneous pore structure,

- Providing softness and crispness on the pizza base,

- Providing extra flavor to the pizza,

- Ability to carry the ingredients placed on the pizza base in the desired manner,

- Preventing the formation of bubbles on the pizza surface after cooking,

- Providing the ability to preserve its freshness for a long time,

- Providing the ability to preserve its crispness and shine for a long time,

- Providing the ability to obtain standard products.

ADK MATE 400 PİZZA

Bagel

Usage Area

In Simit Flour Production Processes;

10-30 gr / 100 kg

Benefits

- In the Simit Production Process,

An elastic structure is obtained in the dough. - The pores inside the dough are small and regular.

- It supports dough stability during fermentation development.

- It provides a crispy structure and bright crust color in the final products.

- It preserves its freshness for a long time.

ADKMATE825

ADK MAYE 825 SMT

ADK MATE 105

Usage Area

Our main vitamins and minerals;

Iron (Fe), Zinc (Zn), Vitamin 82, Vitamin 83, Vitamin 89, Vitamin 86, Vitamin 812, Vitamin A, Vitamin D

World countries vitamin and mineral premixes,

ADK MATE 105 BNN ADK MATE 105 DJBT ADK MATE 105 VNZ ADK MATE 105 FLSTN ADK MATE 105 GN ADK MATE 105 FLPN ADK MATE 105 YMN ADK MATE 105 WFP

The requested content may vary depending on the country.

Usage Rates: 250 gr / ton

Benefits

One third of the world’s population is deficient in vitamins and minerals. Famine and malnutrition are the main reasons for this. In many countries, fortified cereals have mandatory legislation. Therefore, the increasing demand for vitamin and mineral premixes for flour fortification is increasing every day.

ADK MATE 105 BNN

ADK MATE 105 FLPN

ADK MATE 105 GN

ADK MATE 105 DJBT

ADK MATE 105 FLSTN

ADK MATE 105 VNZ

ADK MATE 105 WFP

ADK MATE 105 YMN